Electrical Process Heaters for Power Generation

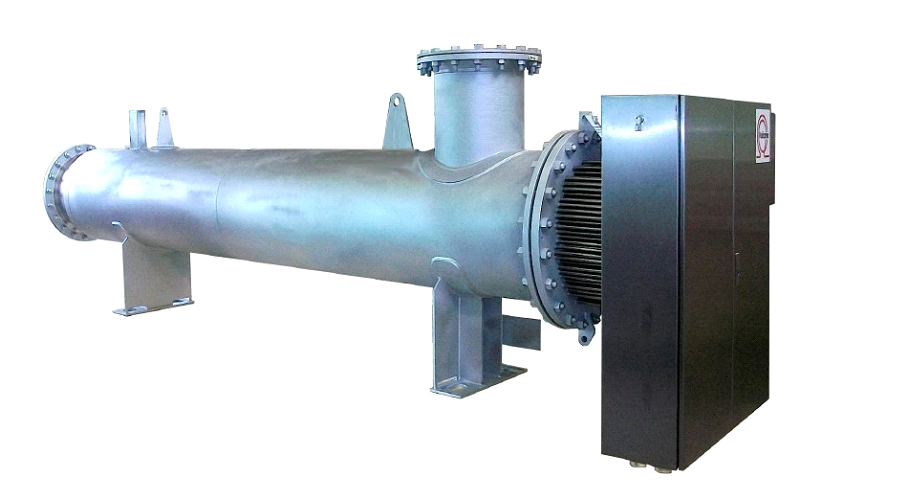

Fuel gas can be a mixture of methane, ethane, propane, butane and other hydrocarbons. Eventus supplies electric fuel gas heaters are suitable as pre heaters and super heaters in fuel gas onditioning systems in the onshore and offshore sectors.

The elements and internals are typically constructed in stainless steel and the tube-sheet in carbon steel.

Eventus supplies fuel gas heaters have an operating temperature range of −30°–350°C (−22°–662°F).

Available in capacities from 1–10000 kW, electric process heaters have smaller footprints. They are virtually 100% efficient and there is no risk of fouling that creates a need for frequent cleaning.

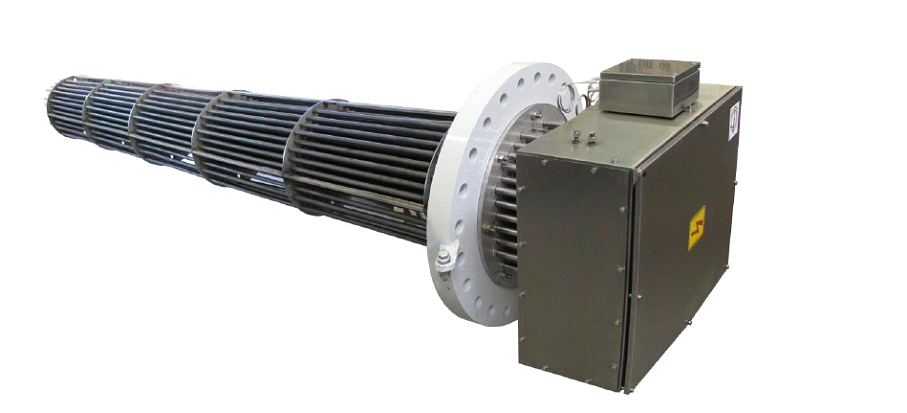

They are used in power plants for heating crude oil for separation and transportation. Eventus supplies a range of crude oil heaters, starting from a few kWs up to 3 MW in single shell. A higher power rating can be achieved using multiple shells in series or parallel.

For heating crude oil, electric inline process heaters in a pipeline have advantages over other technologies. Since they do not need to recover heat from another system, they can be installed anywhere in the pipeline as long as there is power available.

In crude oil heaters, the elements and internals are constructed of alloy 800, and the vessel and tube-sheet are of stainless steel of the types ASTM 321H, 316Ti or alloy 800.

Eventus supplies crude oil heaters have an operating temperature range of 0°–200°C (32°–392°F).

Available in capacities from 1–10000 kW, with smaller footprints. They are virtually 100% efficient and there is no risk of fouling that creates a need for frequent cleaning.

Heater control systems

Every electric process heater needs a control panel to control the current. The electric heater is only as good as the panel that is controlling it. We offer a wide range of control options to suit client requirements.

For large heater loads the power is broken into a number of banks. Thyristor control is recommended for all process heaters because the current can be controlled. However, contactors can be used for some stages by utilizing a load sequencer to reduce the losses across the thyristors and aid in amping controlled steps. Putting the heater in remote mode will allow the DCS system to control the heater centrally. Putting the heater in local mode allows the heater to be controlled locally and is useful during erection, commissioning, maintenance and repair operations.

- Panel indications

- Power on/off

- Heater on/off

- Element over-temperature

- Heater over-temperature

- Panel over-temperature

- Earth fault/leakage

- Current (I)

- Voltage (V)

- Local controls

- Heater on/off

- Trip reset

- Local/remote control

- Door mounted potentiometer

- Lamp test

- Earth leakage reset

- Emergency shut down